Amptrans Energy LLP is exclusive Indian channel partner for Jiangsu. For quality & high end products of Amorphous & Nanocrystalline ribbons & cores.

Jiangsu Guoneng Alloy Technology Co,, Ltd established in 2014, registered capital $16 million USD, covers an area of 40,000m3 with abt 200 staff, located in Yixing city (Jiangsu Province) with convenient and quick transportation (2 hours away from Shanghai).

Guoneng is an innovative enterprise engaging in R&D and manufacturing amorphous ribbon, amorphous cores, nanocrystalline ribbon, nanocrystalline cores and transformers with ISO9001:2008 and ISO14001:2004 certification along with more than 20 China patents. Together established jointly 'Jiangsu Guoneng New Materials Research and Development Center' with Shandong University of Science And Technology.

Guoneng always believe and follow: Quality First+Integrity Based+Quickest Solution. Guoneng has occupied 30% domestic market, also looking forword to making friends with you, working with you, and moving towards a better tomorrow with you!

2. INDIA OPERATIONS

BRIEF ON INDIA OPERATIONS :

(i) Indenting division: Amptrans Energy LLP is exclusive Indian channel partner for Jiangsu. For quality & high end products of Amorphous & Nanocrystalline ribbons & cores.

(ii) Manufacturing division: Amptrans has also set up state of art manufacturing facility at Banglore, India for manufacturing amorphous cores.

3. CRGO

BRIEF ON CRGO OPERATIONS :

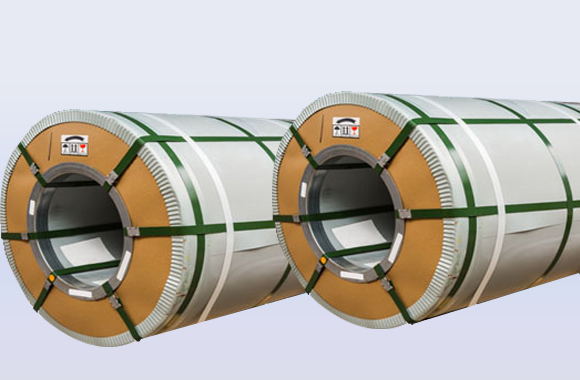

CRGO material has the least figure of maximum core loss in the rolling direction. With the increased shearing angle to the rolling direction, the core loss at any particular flux density goes up and becomes generally highest in the transverse direction. Because of this it is possible to use CRGO in static electrical machines which include all types of power transformers, distribution transformers, etc.

Manufacturing Mills of CRGO Steel do guarantee the core loss figure at flux density of 1.5 Tesla for conventional grain oriented steel and at 1.7 Tesla in case of HI-B and HI-B-LS steel. The grades of material popularly used are M-3, M-4, M-5 and M-6. We also use, for special requirements of the customers, HI-B Material designated as MOH, TRAN-COR H, ZH, ZDKH and ZDMH.

4. CRNGO

BRIEF ON CRNGO OPERATIONS :

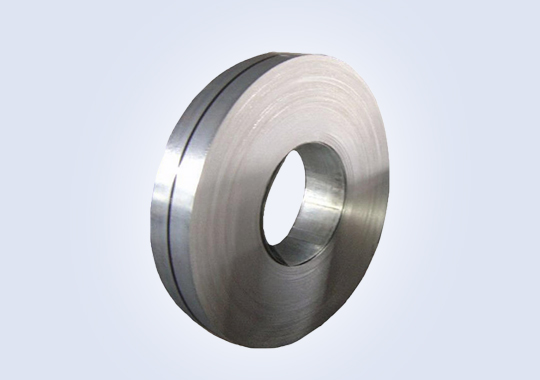

Electrical steel made without special processing to control orientation,, Non-Oriented Steel, usually has a silicon level of 2 and 3.5% and has smaller magnetic properties in all directions I.E., it is isotropic. Colled-Rolled Non-Grain-Oriented Steel is often abbreviated to CRNGO. Cold rolled Non-Oriented Electrical Steel (Non-Oriented Electrical Steel) the term oriented, when used in conjuction with electrical steels, refers to a crystal structure having magnetic properties that are materially better in a given direction.

Difference between CRGO and CRNGO - CRGO needs precise alignment due to its anisotropy (The properties that are different along different directions are anistropic properties) but CRNGO can respond to flux changes in all directions (I.E., its properties are isotropic)